Introduction

The multi-media filter is a water filtration system that uses multiple layers of filter media to

remove particles and impurities from water. Unlike single-media filters that use only one filter

material, multimedia filters combine different materials, each with a specific function, to achieve

more efficient filtration. For example, quartz sand removes suspended matter from water, activated

carbon decolorizes and removes suspended matter from water, manganese sand removes iron and manganese

and suspended matter from water, fiber balls and walnut shells remove oil from water, etc.

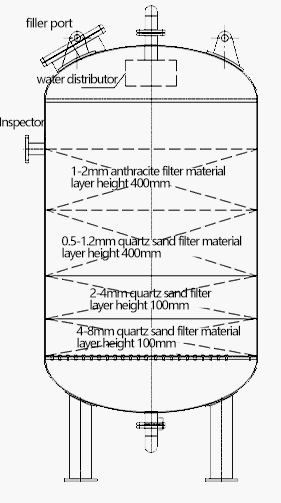

The most common multimedia filter consists of sand and anthracite as the filtration media. The sand

has smaller grains and is heavier than the anthracite. This ensures that the sand layer settles

beneath the anthracite and provides finer filtration. A well operated Multimedia Filter can remove

particulates down to 20 microns. This multi-layered approach allows multi-media filters to remove a

wide range of particle sizes, from large sediments to fine particulates, resulting in cleaner and

clearer water.

Components

1.Filter Tank: This component will house the filtration media, it is either stainless steel, FRP or

epoxy coated steel. Metallic tanks can handle higher temperatures and pressure

2. Media: This is the filtration media that includes different layers of gravels, quartz sand, and

anthracite. This will depend on the quality of the filtered water that is needed.

3. Internal upper and bottom distributors: The bottom distribution system will prevent the media from

escaping, while the upper distribution system will distribute the flow harmonically during the service

cycle. The materials of construction can either be schedule PVC or stainless steel. If your

application has a high temperature water, we recommend stainless steel internals, tank and face

piping.

4. Valves: The valves open and close according to the different cycles. They could be automatic

electric or pneumatic valves for automatic water filters, or manual valves for manual filters. For

seawater, it is recommended to use nonmetallic valves. Some industries do not allow electric

valves.

5. Controller: This component will control the automation of your filter. This could be a PLC. This is

usually a preference based on the main control in the facility or the building.

6. Face piping: Face piping will connect all valves that control the different cycles. It could be

schedule PVC, stainless steel or epoxy coated carbon steel. The material of the piping depends on the

temperature or operating pressure, and if it’s an indoor or outdoor application.

Application

· Suspended solids and turbidity reduction

· Iron and manganese removal

· Groundwater remediation

· Pre-treatment for RO/NF and membrane system

· Pre-treatment for UV sterilizers

· Filtration of grey, river or surface water

· Tertiary treatment for waste water

· Cooling tower and heat exchanger

· Water features (fountains, etc.)

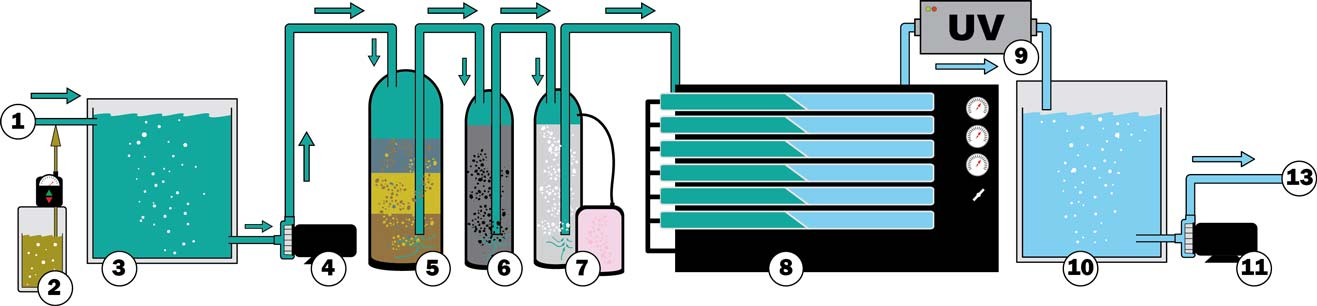

1. Pretreatment media filter for reverse osmosis (RO):

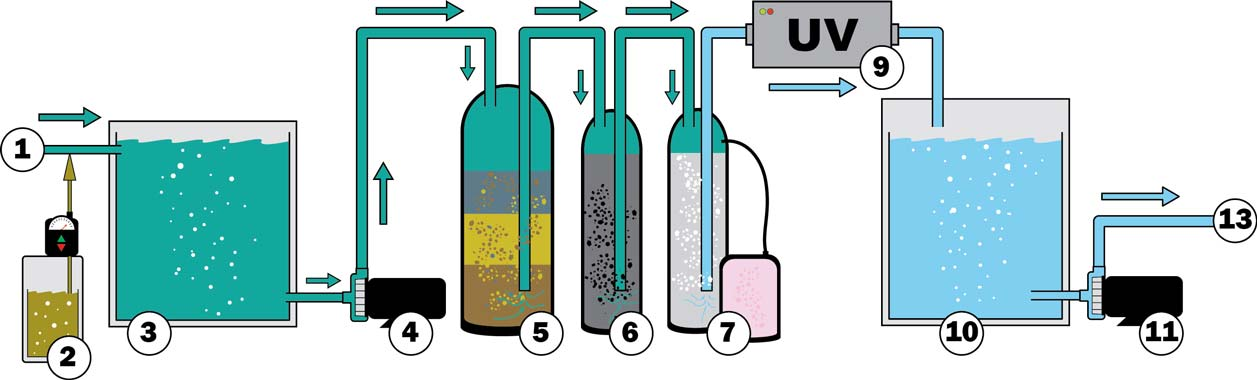

2. Pretreatment media filter for ultraviolet (UV):

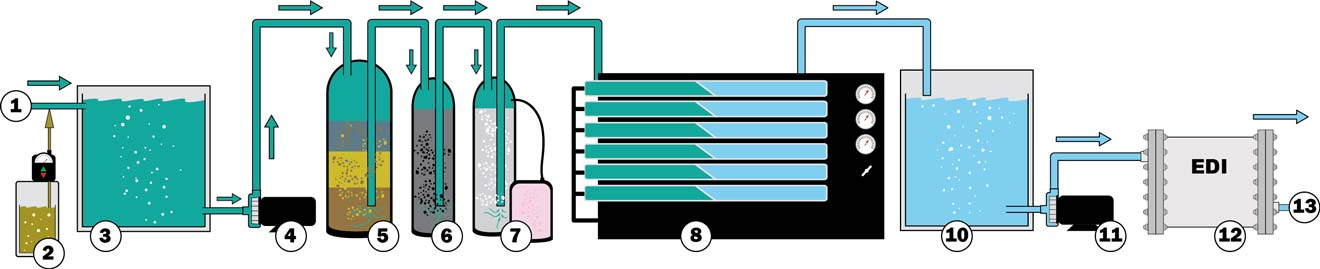

3. Pretreatment media filter for electrodeionization (EDI):

4. Pretreatment media filter for ion exchange:

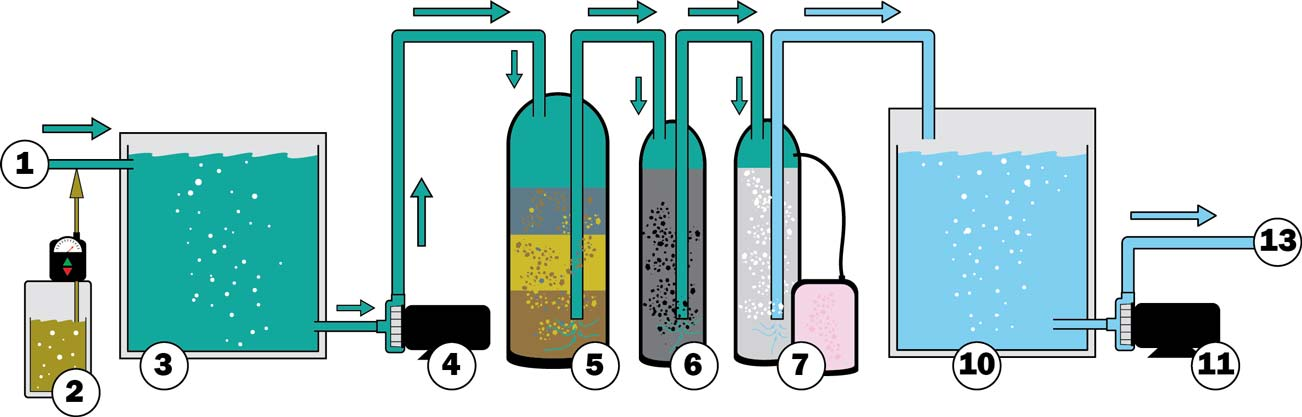

①Raw Feed Water

②Chemical Dosing

③Raw Feed Water Tank

④Feed Pump

⑤Multimedia Filter

⑥Carbon Filter

⑦Ion Exchange Filter

⑧Reverse Osmosis System

⑨Ultra Violet Sterilizer

⑩Product Water Tank

⑪Product Water Pump

⑫Electro-Deionization

⑬Point of Use