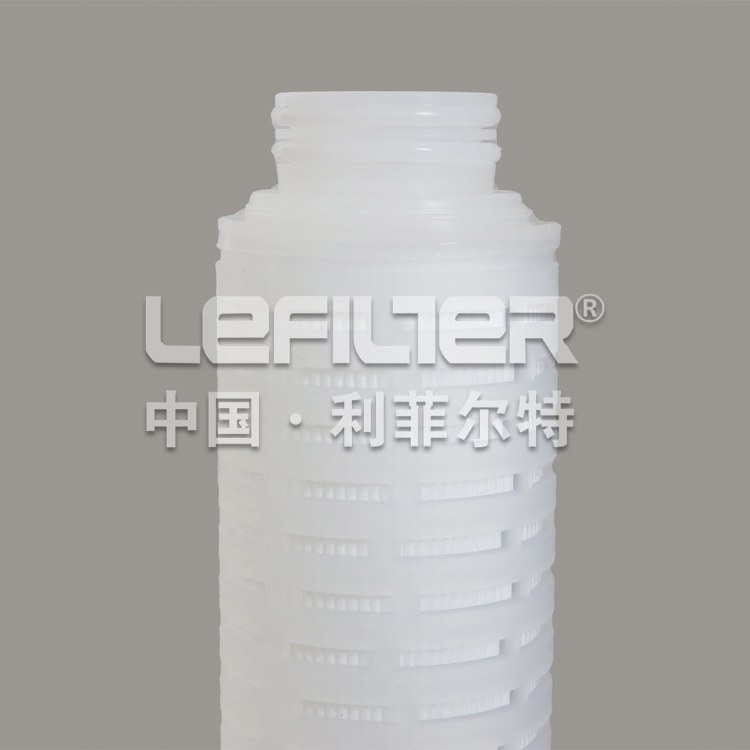

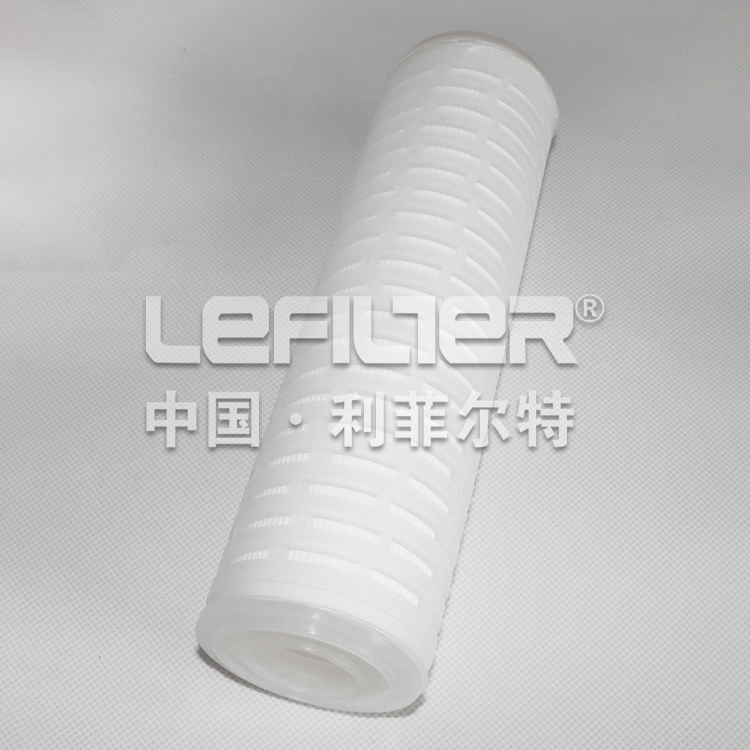

Pleated Cartridge Filter: Enhancing Filtration Efficiency and Flow Performance

DATE:2025-01-04 Number of views: 1 Source:jiaxiangting

Pleated Cartridge Filters are designed to offer superior filtration performance while maintaining optimal system efficiency. These filters stand out for their exceptional ability to remove a wide range of contaminants from water, including suspended particles, sand, rust, and other impurities. The pleated design, with its increased surface area, enables these filters to effectively trap particles without significantly restricting flow rates, making them a versatile choice for numerous industrial and commercial applications. This article explores the key features of Pleated Cartridge Filters, focusing on their high filtration performance, flow characteristics, and particle size filtration capabilities.

High Filtration Performance

The primary advantage of a Pleated Cartridge Filter lies in its ability to achieve high filtration efficiency. Unlike traditional filters, which may only capture a limited range of contaminants, the pleated design offers a larger surface area, allowing it to trap more particles and extend the filter's operational lifespan. This increased surface area is particularly beneficial in applications where water quality is crucial, such as in food and beverage processing, pharmaceuticals, and chemical industries.

The efficiency of Pleated Cartridge Filters is largely due to their fine filtration capabilities, capable of removing fine particles such as sediment, dust, algae, and other suspended solids from water. For example, in the case of a Membrane Filter Cartridge, the membrane's precise pores ensure that even the smallest contaminants are effectively filtered out, making it ideal for high-purity applications. Additionally, PTFE Cartridge Filters are known for their ability to filter harsh chemical substances and high-temperature fluids, offering a broader range of industrial applications, from water treatment to chemical filtration.

The pleated structure, compared to a simple wound or string filter, allows for a more even distribution of flow, which reduces the likelihood of clogging. This means that users can enjoy longer service times between replacements, reducing downtime and maintenance costs while maintaining a high level of performance.

Balancing Flow and Resistance

One of the main challenges in filtration is achieving a balance between high filtration efficiency and low flow resistance. Pleated Cartridge Filters excel in this regard. While they offer exceptional filtration performance, they are also designed to minimize water flow resistance. This feature makes them ideal for systems that require consistent flow rates while maintaining a high standard of water purity.

In many filtration systems, excessive pressure drop due to high resistance can lead to increased energy consumption and reduced system efficiency. However, thanks to the pleated design, these filters can maintain a low-pressure drop, even in high-flow applications. This results in less strain on the pumping system, translating into energy savings and extended equipment life. The Pleated Water Filter Cartridge performs particularly well in systems that need to process large volumes of water, as the increased surface area allows for better distribution of the flow, leading to less clogging and less backpressure.

The ability to balance filtration efficiency and flow resistance is a crucial factor for industries that deal with varying flow rates and water quality. For example, in water treatment plants, where constant flow rates are essential, a Membrane Filter Cartridge can provide fine filtration without negatively impacting the system’s overall efficiency. This ensures both consistent water quality and operational stability.

Particle Size Filtration Capabilities

Another critical aspect of Pleated Cartridge Filters is their ability to filter out a wide range of particle sizes. The pleated structure allows for various filter media options, each designed to handle different levels of particle filtration. Depending on the material used for the filter, these cartridges can capture a broad spectrum of particle sizes, ranging from coarse debris to fine sub-micron particles. This makes them adaptable to different filtration needs across various industries.

For instance, PTFE Cartridge Filters are particularly effective in capturing very fine particles and contaminants, such as bacteria, viruses, and other microorganisms. Their high-precision filtration makes them an excellent choice for applications where sterilization and high-purity filtration are necessary, such as in the pharmaceutical and biotechnology industries. On the other hand, the Pleated Water Filter Cartridge provides a more versatile solution for applications where a combination of particle sizes must be removed, offering a balance between coarse filtration and finer particulate capture.

The pleated design ensures that the filter's media remains evenly distributed, providing a consistent and reliable filtration performance. In addition, the ability to change the filtration material according to the specific application requirements allows users to tailor the filter’s performance to their exact needs. Whether the task involves removing large debris from water or capturing smaller suspended solids, the Pleated Cartridge Filter is adaptable to meet a wide range of challenges.

Applications in Various Industries

The versatility of Pleated Cartridge Filters makes them ideal for use in numerous industries. Their ability to provide high-efficiency filtration while maintaining low-flow resistance ensures they are well-suited for a variety of applications, including:

1.Water Treatment: Pleated filters are commonly used in municipal and industrial water treatment plants to ensure the removal of suspended solids and impurities, offering both large-scale and fine filtration solutions.

2.Food and Beverage: In the food and beverage industry, where purity and cleanliness are paramount, these filters can be used to remove contaminants such as sand, rust, and other impurities, ensuring safe and high-quality products.

3.Pharmaceutical and Biotech: For applications that require the filtration of microorganisms and other fine contaminants, PTFE Cartridge Filters provide a high level of performance, essential for maintaining sterile environments.

4.Chemical Processing: In chemical manufacturing, where corrosive substances and fine particles are often present, Membrane Filter Cartridges and PTFE Cartridge Filters provide the necessary filtration while maintaining durability and resistance to harsh chemicals.

5.Oil and Gas: In the oil and gas industry, the filtration of various liquids is essential to maintain operational efficiency. Pleated Cartridge Filters are used to remove particles from drilling fluids, coolants, and other industrial fluids.

Conclusion

Pleated Cartridge Filters offer a highly efficient solution for a variety of filtration challenges. Their high filtration efficiency, low-flow resistance, and ability to handle a wide range of particle sizes make them a versatile choice for industries that demand consistent performance and reliability. Whether used in municipal water treatment systems, the pharmaceutical industry, or chemical processing plants, these filters provide superior filtration while maintaining the operational efficiency of the system. With options like Membrane Filter Cartridges, PTFE Cartridge Filters, and Pleated Water Filter Cartridges, businesses can tailor their filtration systems to meet their specific needs, ensuring that water and other liquids are purified to the highest standards.