Pleated Cartridge Filter: Enhancing Filtration Efficiency and Cost-Effectiveness

DATE:2025-01-07 Number of views: 1 Source:jiaxiangting

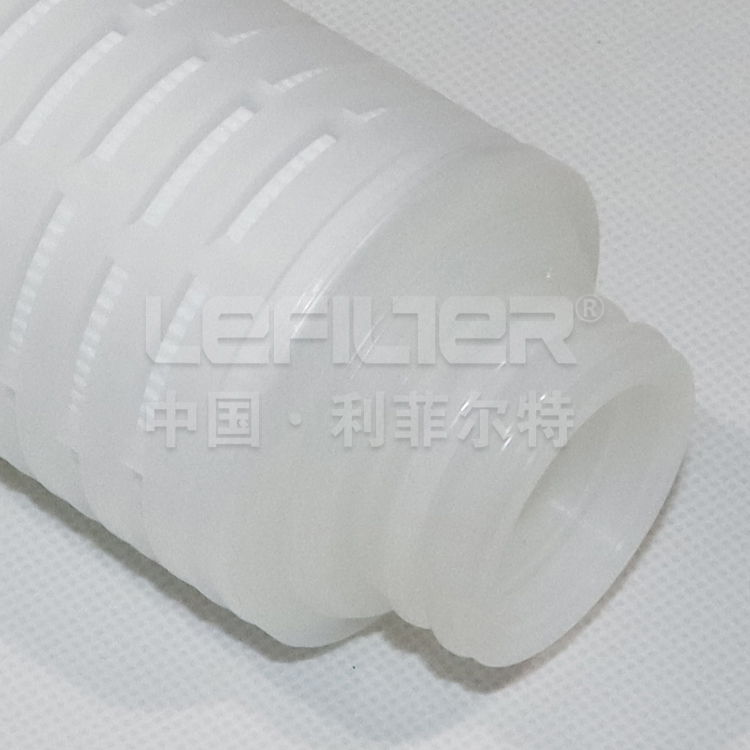

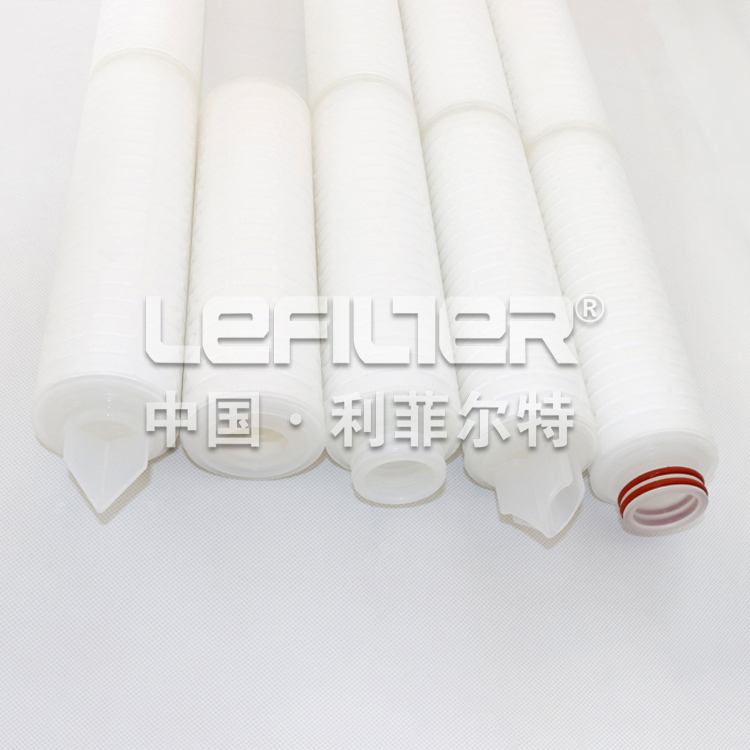

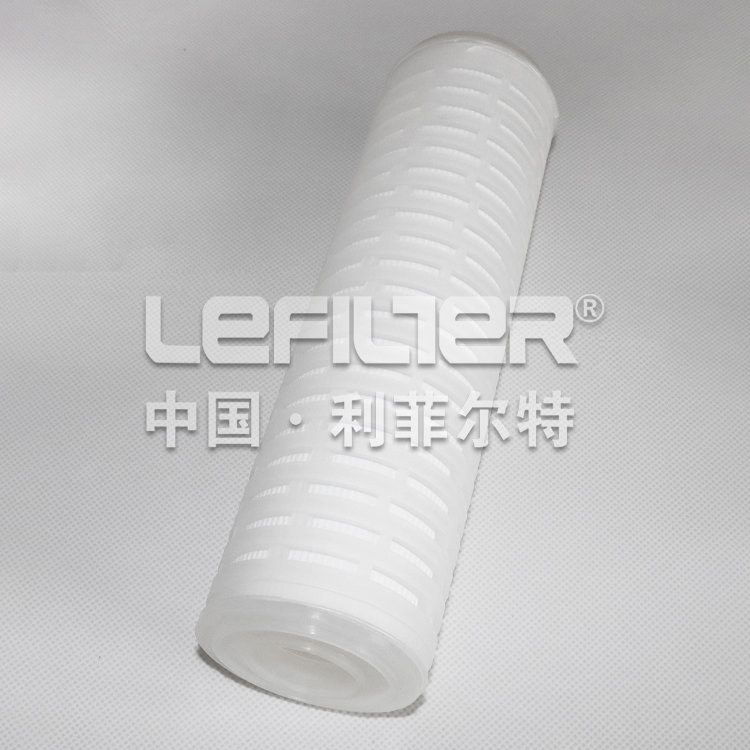

The Pleated Cartridge Filter is a high-performance filtration solution designed to improve filtration efficiency while offering significant advantages over traditional and membrane-based systems. Its unique pleated structure maximizes surface area, enabling it to capture larger volumes of contaminants and extend operational lifespans compared to other filter types. In this article, we will explore how the Pleated Cartridge Filter compares to other filtration systems, specifically membrane filters and traditional cartridge filters, emphasizing key benefits such as lower maintenance costs, higher flow rates, and better overall efficiency.

Pleated Cartridge vs. Membrane Filtration Systems

When discussing filtration systems, it is essential to understand the core differences between Pleated Cartridge Filters and membrane-based systems, such as the Pleated Membrane Filter. While both systems serve the primary purpose of removing contaminants from liquids, the manner in which they achieve this, as well as their operational costs and performance levels, differ significantly.

1. Filtration Efficiency and Mechanism of Action

Membrane filtration systems, such as the Pleated Membrane Filter Cartridge, typically rely on semi-permeable membranes that allow certain particles to pass through while blocking others based on size or charge. These systems are highly efficient in terms of providing selective filtration for particles, down to microscopic or even molecular levels, making them ideal for high-purity applications, such as in pharmaceutical or semiconductor industries. However, this high precision also means that membrane filters tend to have a much smaller surface area for filtration, which can result in faster clogging and more frequent maintenance.

In contrast, the Pleated Cartridge Filter, through its pleated design, provides a much larger surface area for filtration. This increased surface area allows it to handle higher flow rates and capture more particulate matter before requiring maintenance. While it may not provide the same level of filtration precision as membrane filters, it offers a more practical and cost-effective solution for applications that do not require ultra-purified filtrates.

2. Maintenance Costs and Frequency

One of the most significant advantages of the Pleated Cartridge Filter over membrane systems is its lower maintenance costs and reduced need for frequent replacements. Membrane filters, especially those using polymeric or PTFE (polytetrafluoroethylene) materials, can be costly to replace, and they often require specialized cleaning procedures, which further contribute to higher operational expenses. In industries where downtime must be minimized, such as in food and beverage production, the Pleated Membrane Filter Cartridge requires careful management to prevent premature failure, which often involves costly chemical cleaning.

By contrast, the Pleated Cartridge Filter, with its robust design and greater surface area, generally experiences fewer clogging issues and can be cleaned more easily, either through backwashing or simple rinsing. This results in a longer lifespan and fewer disruptions to operations, making it an attractive option for industries seeking to reduce overall maintenance expenditures. Additionally, the Pleated Cartridge Filter can typically be replaced at a lower cost than membrane filters, providing further savings in the long term.

3. Flow Rate and Efficiency

The Pleated Cartridge Filter excels in applications where higher flow rates are essential. The pleated design allows for more efficient use of the filtration surface area, leading to less resistance to flow. This feature makes the Pleated Cartridge Filter particularly valuable in applications where large volumes of liquid must be filtered quickly, such as in industrial water treatment or municipal wastewater processing. Membrane filters, while highly efficient in removing fine particles, often struggle to handle high flow rates, requiring larger or multiple membrane units to achieve the same capacity. This not only increases the initial installation costs but also the operational costs due to increased energy consumption and frequent replacement needs.

On the other hand, the Pleated Cartridge Filter’s superior flow rate handling capabilities make it ideal for large-scale filtration tasks where maintaining a steady flow of liquid is essential. Its ability to maintain efficiency without sacrificing throughput sets it apart from membrane filtration systems, which can become more sluggish as they load up with contaminants.

Pleated Cartridge vs. Traditional Filter Cartridges

To further understand the advantages of the Pleated Cartridge Filter, it is useful to compare it with traditional, non-pleated filters, such as depth filters and activated carbon filters. While traditional filters like depth filters provide good performance in capturing suspended solids, they often do so with less efficiency than the pleated alternatives, and they are more prone to clogging due to their lower surface area.

1. Surface Area and Filtration Efficiency

Traditional filters, like the deep bed filters, work by physically trapping particles within the depth of the filter material. These filters tend to have limited surface area for filtration, which means they need to be replaced more frequently as they clog up faster. This limitation directly impacts their overall efficiency, as they require more maintenance and result in greater downtime.

In comparison, the Pleated Cartridge Filter offers a much larger surface area due to its pleated structure, which allows for longer intervals between replacements and better overall filtration efficiency. By maximizing the surface area within a given volume, the Pleated Cartridge Filter captures contaminants more effectively, reducing the frequency of filter changes and the operational disruptions that result from them. This means that industries relying on traditional filters can achieve more consistent performance with fewer interruptions.

2. Longevity and Cost-Effectiveness

Traditional filters, including activated carbon filters, have their own specific applications—such as removing organic contaminants or odors—but they tend to wear out quickly when filtering particulate matter or larger contaminants. As a result, they require more frequent maintenance, which leads to higher long-term costs.

The Pleated Cartridge Filter, with its longer lifespan and ability to handle a higher volume of contaminants, presents a more cost-effective solution. In applications like industrial water treatment, where large quantities of water need to be filtered constantly, the Pleated Cartridge Filter can be more economical in the long run. Additionally, its ability to handle varying flow rates without significant degradation of performance makes it a more versatile and robust option compared to traditional filters.

3. Cleaning and Maintenance

Another major benefit of the Pleated Cartridge Filter is its ease of cleaning and maintenance. Unlike depth filters or activated carbon filters, which may need to be replaced after they become saturated, the Pleated Cartridge Filter can often be cleaned and reused several times before replacement becomes necessary. This ability to be cleaned and reused makes it a more sustainable option for industries looking to reduce waste and lower their environmental footprint.

Advantages of PTFE Pleated Filter Cartridges

PTFE Pleated Filter Cartridges are particularly well-suited for applications that require filtration of aggressive chemicals, oils, or solvents. The PTFE material is chemically resistant, ensuring that the filter maintains its structural integrity even in harsh environments. This makes PTFE Pleated Filter Cartridges a popular choice in industries such as pharmaceuticals, biotechnology, and chemical processing, where the need for purity and durability is paramount.

1. Chemical Resistance and Durability

The PTFE material used in these filters offers outstanding chemical resistance, making them ideal for environments where other materials might degrade. Whether dealing with acids, alkalis, or solvents, PTFE Pleated Filter Cartridges offer a superior level of protection, ensuring longer operational lifespans and fewer filter replacements. This added durability also leads to a lower total cost of ownership, as users can rely on the filter to maintain performance even under challenging conditions.

2. High Performance in Critical Applications

The high-performance characteristics of PTFE Pleated Filter Cartridges also make them an attractive option for critical applications where even the slightest contamination can cause significant issues. Whether used in food and beverage processing or the production of sensitive chemicals, PTFE Pleated Filters provide an additional layer of security, ensuring that contaminants are removed effectively while maintaining the purity of the end product.

Conclusion

The Pleated Cartridge Filter stands out as an efficient, cost-effective solution for a wide range of filtration applications, offering advantages in flow rate, filtration efficiency, and maintenance cost over both membrane filtration systems and traditional cartridge filters. Whether used in water treatment, industrial filtration, or chemical processing, the Pleated Cartridge Filter provides exceptional filtration performance with lower maintenance needs and longer service life, ensuring that industries can achieve cleaner, more reliable results at a reduced operational cost. For applications that require even higher chemical resistance, the PTFE Pleated Filter Cartridge adds a layer of durability and performance, making it a powerful choice for industries demanding the highest standards of filtration.