Large Flow Filter Element: Maximizing Filtration Efficiency with Advanced Design

DATE:2025-01-10 Number of views: 1 Source:jiaxiangting

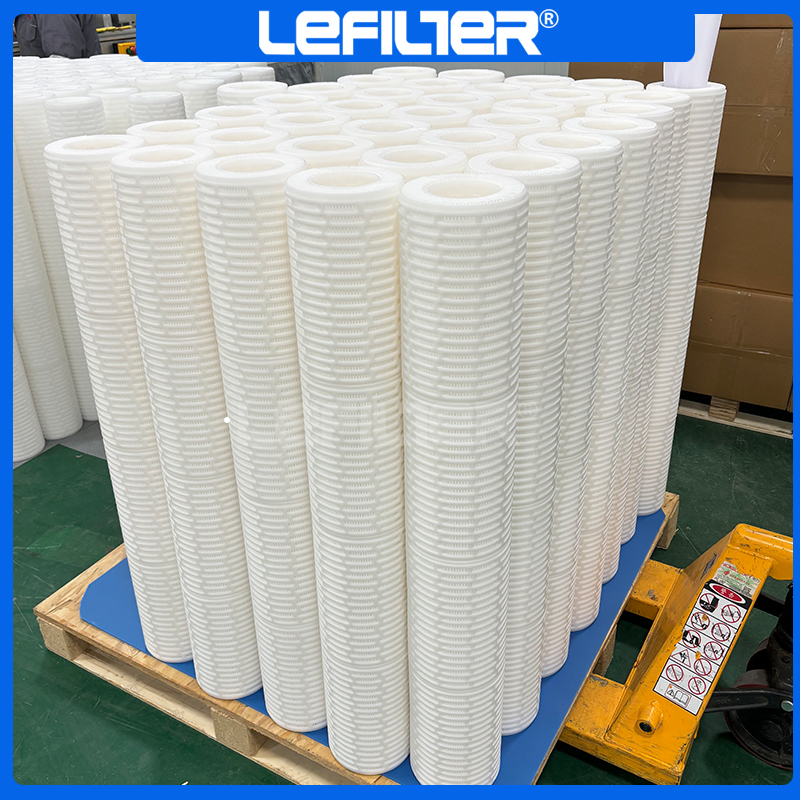

Large Flow Filter Element is a cutting-edge solution designed to meet the growing demands for high-volume filtration in industries such as water treatment, oil and gas, chemical processing, and food production. With the increasing need for handling large flow rates while maintaining high filtration efficiency, these elements offer a significant advantage in both operational capacity and longevity.

Filtration Media: Key Materials and Their Impact on Performance

The performance of any filter is largely determined by the materials used in its construction. For Large Flow Filter Elements, selecting the right filtration media is crucial to achieving optimal results. Among the most commonly used materials are polypropylene (PP), fiberglass, and stainless steel mesh. Each of these materials has unique properties that contribute to the overall effectiveness of the filter, and understanding their advantages and limitations helps in choosing the best option for a specific application.

1.Polypropylene (PP) Filtration Media

Polypropylene is one of the most widely used materials in the production of High Flow Rate PP Pleated Filter Cartridges. This material is known for its exceptional chemical resistance, durability, and ability to withstand high temperatures, making it an ideal choice for filtering a wide range of fluids, from water to various industrial chemicals.

The primary advantage of polypropylene filters lies in their cost-effectiveness and ease of use. PP Pleated High Flow Filter Cartridge Water, for example, is highly effective in removing particulates, bacteria, and other contaminants from water systems. Its pleated design increases surface area, allowing for longer filter life and improved efficiency under high-flow conditions.

However, there are some limitations. While polypropylene filters offer excellent resistance to acids and bases, they may not be suitable for extreme temperatures or highly aggressive solvents, which may degrade the material over time. Therefore, it is essential to consider the chemical composition of the fluid being filtered when selecting polypropylene-based filter elements.

2.Fiberglass Filtration Media

Fiberglass is another commonly used material in Pleated Water Filter Elements due to its superior filtration performance, especially in high-flow applications. Fiberglass filters are highly efficient at capturing fine particles, and their structure provides a high dirt-holding capacity. As a result, these filters tend to have a longer service life compared to traditional filters, which means they require less frequent replacement and maintenance.

The main advantage of fiberglass filters is their ability to handle fine particulate matter in liquids, making them particularly suitable for use in industries such as pharmaceuticals, food and beverage, and chemicals, where purity and precision are paramount. They also perform well in both low- and high-flow conditions, offering excellent filtration efficiency even in demanding environments.

On the downside, fiberglass is more fragile compared to polypropylene and may be more susceptible to damage under extreme pressure or in applications that involve high mechanical stress. Additionally, fiberglass filters tend to be more expensive than polypropylene-based filters, which may be a consideration for businesses with budget constraints.

3.Stainless Steel Mesh Filtration Media

Stainless steel mesh is commonly used in High Flow Cartridge Filters for industrial applications that require durability, resistance to corrosion, and the ability to handle aggressive fluids. Stainless steel mesh filters provide excellent mechanical strength, making them suitable for heavy-duty applications such as oil and gas filtration or in systems that require high-temperature resistance.

The most significant advantage of stainless steel mesh is its reusability. Unlike disposable filters, stainless steel mesh can be cleaned and reused multiple times, making it a more cost-effective option in the long run for industries with high filtration demands. Additionally, stainless steel is chemically resistant and performs well in a wide range of temperatures and pressures.

However, stainless steel mesh filters tend to have a lower filtration efficiency compared to other materials such as fiberglass, particularly for fine particles. This makes them more suitable for applications where the removal of coarse particles is required, rather than fine contaminants.

Structural Design: Durability, Pressure Resistance, and Stability

The structural design of a High Flow Cartridge Filter is as important as the filtration media itself, especially when dealing with large volumes of fluid under varying pressure conditions. These filters must be able to withstand not only high flow rates but also high pressure, corrosion, and potential clogging, all of which could compromise the system’s stability and efficiency. A well-designed filter element ensures the integrity and long-term performance of the filtration system.

1.Pressure Resistance and Strength

One of the most critical design features of Pleated High Flow Filter Cartridges is their ability to withstand high pressure. The filtration media is often pleated to increase surface area, which improves filtration capacity without increasing the size of the filter. This pleated structure also enhances the strength of the filter element, allowing it to resist pressure surges and maintaining consistent performance even under extreme operating conditions.

The structural design incorporates durable materials that provide reinforcement against high pressures. In applications such as chemical processing or oil and gas filtration, where high-pressure systems are common, the filter elements must be engineered to handle surges and ensure that they do not collapse or lose their structural integrity over time.

2.Corrosion Resistance

In addition to pressure resistance, the filter element’s resistance to corrosion is another essential consideration, particularly when filtering fluids that are acidic, alkaline, or contain corrosive particles. Filters with corrosion-resistant materials, such as stainless steel, are able to withstand exposure to harsh environments without degrading, ensuring that the filtration system remains functional for an extended period of time.

For industries that deal with corrosive liquids or gases, incorporating High Flow Rate PP Pleated Filter Cartridges or stainless steel mesh filters into the filtration system provides an added layer of protection, ensuring that the filter does not become a point of failure due to corrosion.

3.Anti-Clogging and Contaminant Holding Capacity

A significant advantage of Pleated Water Filter Elements is their increased surface area, which enhances their ability to capture contaminants while maintaining a low-pressure drop. This feature is particularly important in high-flow applications, where the filter must handle large volumes of fluid without becoming clogged too quickly. The pleated design allows for a greater dirt-holding capacity, reducing the frequency of maintenance and filter replacement.

In addition to the pleated design, the support structure and design of the filter housing are crucial in preventing the buildup of contaminants that could clog the filter and reduce its efficiency. High-quality filter housings are designed to maintain the filter’s stability and ensure that it remains in optimal condition throughout its service life.

Conclusion: Choosing the Right Filter for Your Needs

The Large Flow Filter Element is an essential tool in industries requiring high-flow filtration, offering outstanding performance across various applications. By selecting the appropriate filtration media, such as polypropylene, fiberglass, or stainless steel mesh, and ensuring a durable and well-designed structure, these filters provide reliable and efficient filtration under even the most demanding conditions.

The High Flow Cartridge Filter is available in various designs and materials to suit the specific needs of industries such as water treatment, oil and gas, food and beverage, and pharmaceuticals. The advanced pleated design ensures maximum surface area and dirt-holding capacity, while the high-strength construction guarantees long-term durability, even under extreme pressure and corrosive environments.

Whether it’s optimizing water treatment, ensuring the purity of chemical processes, or enhancing oil and gas filtration, the Pleated High Flow Filter Cartridge Water provides a dependable and cost-effective solution for large-flow filtration needs.

FAQ:

Q: How long do High Flow Filter Cartridges typically last?

A: The lifespan of a High Flow Filter Cartridge depends on factors like flow rate, the nature of the contaminants, and operational conditions. On average, they can last anywhere from several months to a few years. Regular maintenance and cleaning can extend their lifespan.