Pleated Cartridge Filter: Revolutionizing Filtration with Advanced Materials and Smart Technology

DATE:2025-01-10 Number of views: 1 Source:jiaxiangting

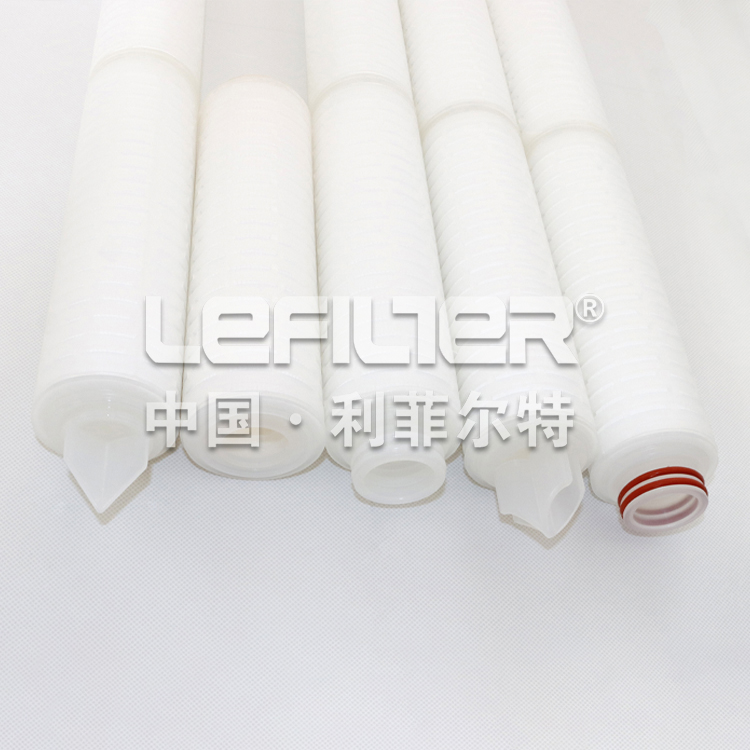

The Pleated Cartridge Filter has become a critical component in modern filtration systems, offering unparalleled performance in terms of efficiency, lifespan, and operational cost savings. With the continuous evolution of materials and technology, these filters are now better equipped than ever to handle the increasingly complex needs of various industries.

Innovative Materials and Advanced Technologies in Pleated Cartridge Filters

One of the driving forces behind the increasing popularity of Pleated Cartridge Filters is the ongoing development of new materials and technologies that significantly enhance their filtration efficiency. Recent advancements have made it possible for these filters to capture finer particles and provide more consistent performance over longer periods, all while maintaining a relatively low pressure drop across the system.

Among the most groundbreaking innovations is the introduction of nanofibers in the production of PTFE Membrane Filter Cartridges. Nanofibers are fibers with diameters that are measured in nanometers, which is much smaller than the traditional filter fibers. This enables the PTFE Membrane Pleated Filter to achieve a higher surface area and finer filtration capabilities, making it more effective at trapping microscopic particles that traditional filters might miss. The fine structure of the nanofibers not only improves filtration efficiency but also contributes to a significant reduction in pressure drop, which helps maintain optimal airflow or fluid flow in the system.

Another important development is the application of antimicrobial coatings to PTFE Filter Cartridges. These coatings prevent the growth of bacteria, fungi, and other microorganisms on the filter surface, making the filter more hygienic and suitable for industries where cleanliness is paramount, such as the food and beverage or pharmaceutical sectors. By preventing microbial growth, the antimicrobial coating also extends the lifespan of the filter, ensuring more consistent performance over time.

High-performance synthetic materials are also becoming more prevalent in Folded Cartridge Filters, replacing traditional materials like cellulose or polyester. Synthetic fibers such as polypropylene, polyester, and polytetrafluoroethylene (PTFE) offer superior resistance to chemicals, heat, and mechanical stress, making them ideal for use in harsh environments. These materials also contribute to improved filtration efficiency, as they allow for the construction of pleated filters with better flow dynamics and higher capacity for particulate matter.

The introduction of these advanced materials not only improves the performance of Pleated Cartridge Filters but also expands their application range. From the food and beverage industry to wastewater treatment, these filters are now capable of addressing a much broader spectrum of filtration needs, making them an invaluable tool for industries worldwide.

Smart Filtration Systems: The Next Frontier in Filtration Efficiency

The next significant leap in the development of Pleated Cartridge Filters is their integration into smart filtration systems. These systems use sensors, automation, and real-time monitoring to optimize the filtration process, improving performance, and reducing the need for manual intervention. By leveraging cutting-edge technologies such as the Internet of Things (IoT), smart sensors, and data analytics, modern filtration systems are capable of monitoring the condition of Folded Cartridge Filters and automatically adjusting operations based on real-time data.

For instance, in smart water treatment systems, PTFE Membrane Filter Cartridges can be equipped with sensors that monitor factors like pressure drop, flow rate, and contamination levels in real-time. These sensors collect data on the filter's performance and send it to a central control system, where advanced algorithms analyze the data to predict when the filter needs cleaning or replacement. By continuously monitoring the state of the filter, these smart systems can trigger automatic maintenance actions, such as backwashing or air purging, to ensure optimal performance without human intervention.

The ability to monitor the status of a PTFE Filter Cartridge remotely offers numerous advantages, including reducing the need for manual inspections and ensuring that any potential issues are identified before they lead to system failure. Furthermore, the integration of real-time data analysis allows for predictive maintenance, which can significantly reduce downtime and extend the lifespan of the filter.

For example, in industrial air filtration systems, PTFE Membrane Pleated Filters can be part of a larger system that automatically adjusts fan speeds based on the filter's current performance, ensuring that the system maintains optimal airflow while minimizing energy consumption. The use of predictive analytics also helps identify when a filter is approaching the end of its useful life, allowing for timely replacement and preventing unnecessary downtime or inefficiencies.

Benefits of Smart Filtration Systems in Energy Efficiency and Cost Reduction

The integration of Pleated Cartridge Filters into smart filtration systems brings about a host of additional benefits, particularly in terms of energy efficiency and cost reduction. By optimizing filter maintenance schedules and reducing the need for manual inspections, these systems reduce operational costs associated with filter replacements, cleaning, and labor. Furthermore, the real-time monitoring provided by smart sensors helps ensure that the filtration system operates at peak efficiency, which minimizes energy consumption.

In air filtration systems, for example, the PTFE Filter Cartridge can help reduce energy costs by maintaining a low pressure drop across the filter. By continuously adjusting fan speeds or pump flow rates based on real-time sensor data, smart systems ensure that the system does not expend more energy than necessary to achieve the desired filtration performance. This optimization of energy usage contributes to lower operational costs, making smart filtration systems an attractive investment for industries looking to improve their bottom line while adhering to sustainability goals.

In water filtration applications, smart systems can also help minimize chemical usage and water wastage by optimizing backwashing cycles. Traditional filtration systems often rely on manual schedules for backwashing, which can lead to excessive water use and energy consumption. However, with smart technology, backwashing is only triggered when necessary, reducing both water and energy consumption, thus contributing to a more sustainable and cost-effective operation.

Future Outlook: The Ongoing Evolution of Pleated Cartridge Filters

As the filtration industry continues to evolve, it is clear that the future of Pleated Cartridge Filters lies in the ongoing integration of advanced materials and smart technologies. With the growing demand for higher filtration efficiency, longer filter life, and more sustainable operations, innovations in nanofibers, antimicrobial coatings, and synthetic materials will likely continue to drive the development of even more advanced filtration solutions.

Moreover, as industries increasingly adopt smart technologies, the role of Pleated Cartridge Filters in automated filtration systems will only expand. The ability to monitor, analyze, and optimize filter performance in real-time represents a significant shift in how filtration systems are managed, leading to enhanced efficiency, reduced downtime, and lower operational costs.

In conclusion, the Pleated Cartridge Filter is poised to remain a key player in the filtration industry as it adapts to the needs of modern industries. By leveraging advanced materials like nanofibers, antimicrobial coatings, and high-performance synthetics, and integrating smart technologies for real-time monitoring and maintenance, Pleated Cartridge Filters are revolutionizing the way filtration systems operate, driving both operational efficiency and sustainability. The future of filtration is intelligent, and Pleated Cartridge Filters are leading the charge.