Pleated Cartridge Filter: A Comprehensive Solution for Efficient Filtration

DATE:2025-01-10 Number of views: 1 Source:jiaxiangting

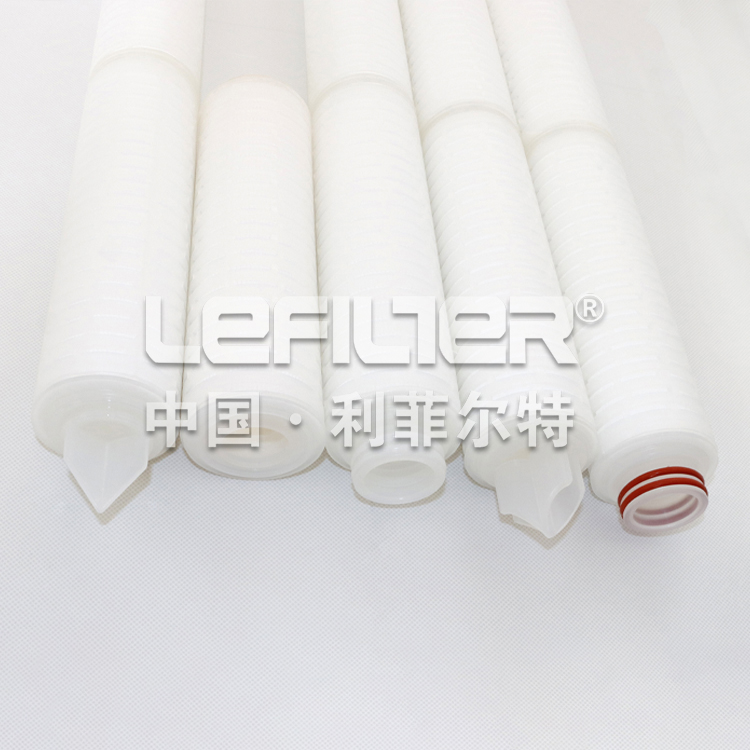

The Pleated Cartridge Filter is rapidly becoming a go-to solution for industries that demand both high filtration efficiency and versatility in a wide range of operational environments. Known for its robust performance, this filter integrates physical filtration, chemical adsorption, and other advanced mechanisms to effectively remove contaminants from various fluids and gases. As industries grow more dependent on high-quality filtration to ensure the purity of their processes, the Pleated Cartridge Filter stands as a critical component in safeguarding system efficiency and enhancing the quality of end products.

Physical Filtration and Chemical Adsorption: How Pleated Cartridge Filters Work

The Pleated Cartridge Filter combines two primary mechanisms of contamination removal: physical filtration and chemical adsorption. These mechanisms work together to provide an effective and efficient filtration solution suitable for diverse applications, from industrial water treatment to air filtration in clean rooms and factories.

Physical Filtration: The First Line of Defense

At its core, the PTFE Filter Cartridge operates as a highly effective physical filter. The pleated design increases the surface area of the filter material, allowing for larger volumes of fluid or air to pass through while retaining contaminants such as particulate matter, dust, and sediments. The PTFE material, known for its excellent chemical resistance and durability, is often used in these filters due to its ability to withstand harsh environments and maintain integrity under extreme conditions.

In the case of 5 Micron PTFE Water Filters, the filtration mechanism is designed to capture particles as small as 5 microns, ensuring a high level of clarity in filtered water. For applications where fine particulate removal is crucial, such as pharmaceutical production or food processing, the PTFE Membrane Pleated Filter provides superior particle retention. The pleated structure enhances the efficiency of the filtration process, enabling the filter to capture more contaminants without requiring excessive space or increasing pressure drop.

The physical filtration process is most effective when the filter is tailored to the specific type of contaminant it is designed to remove. For instance, PTFE Membrane Pleated Filters are especially effective in applications where high filtration precision is necessary, such as in removing heavy metals, bacteria, or particulate matter from industrial water systems.

Chemical Adsorption: Enhancing Filtration Capabilities

While physical filtration is effective for particulate removal, many filtration applications also require the ability to eliminate dissolved chemicals, volatile organic compounds (VOCs), or gases. This is where chemical adsorption comes into play. Some PTFE Filter Cartridges incorporate adsorption media within the filter structure to adsorb and trap chemical impurities. This process is particularly valuable in industries like wastewater treatment, oil refineries, or chemical manufacturing, where the removal of chemical contaminants is as critical as particulate removal.

The PTFE Filter Cartridge Manufacturer typically designs filters with specialized adsorbent materials, such as activated carbon or other reactive compounds, which are integrated into the filter's structure to capture and hold onto undesirable chemicals. For example, certain PTFE Membrane Pleated Filters may incorporate activated carbon layers to efficiently absorb VOCs, heavy metals, or other organic chemicals. This dual mechanism of physical filtration and chemical adsorption ensures that Pleated Cartridge Filters are adaptable to a wide variety of applications, providing a thorough and multi-faceted solution for contaminant removal.

Precision and Flow Control: Ensuring Stable Performance Under Variable Conditions

One of the key benefits of Pleated Cartridge Filters is their ability to maintain consistent filtration efficiency even under varying flow rates and pressure conditions. As fluid dynamics fluctuate in industrial systems, it is essential that filters can operate effectively across a broad range of conditions without compromising performance.

Maintaining Filtration Precision

The 5 Micron PTFE Water Filters are designed to maintain a precise level of filtration regardless of changes in flow rate. The pleated design, with its increased surface area, enables the filter to handle higher flow volumes without experiencing a significant increase in pressure drop. This ensures that the PTFE Membrane Pleated Filter can continue to perform its filtration duties efficiently, even as the system demands more throughput.

In industrial systems where flow rate can fluctuate due to operational variables, PTFE Membrane Pleated Filters help ensure that the filtration process remains consistent. Whether in high-flow applications like industrial air filtration or in systems with lower flow rates, the filter's surface area and structure ensure that it can capture contaminants effectively without requiring constant monitoring or adjustments. The filter's ability to operate under such conditions without clogging or losing efficiency makes it an excellent choice for systems with dynamic conditions.

Pressure Control for Efficient Filtration

In addition to handling variable flow rates, Pleated Cartridge Filters are designed to perform well even under different pressure conditions. Many systems, particularly in industrial water filtration or air purification, experience fluctuations in pressure that could impact filtration quality. When pressure increases, it can lead to higher stress on the filter material, causing an increased risk of filter failure or reduced filtration capacity.

However, the PTFE Filter Cartridge excels in this area. Its pleated construction ensures that the filter can distribute the pressure load evenly across its surface, preventing excessive strain on any single point of the filter. This structure allows the filter to maintain high filtration efficiency without becoming a bottleneck in the system, ensuring stable and reliable performance over time. Whether in high-pressure environments like compressed air systems or in low-pressure applications, the PTFE Membrane Pleated Filter maintains its precision, ensuring consistent results and reducing the likelihood of system downtime.

Versatility in Different Applications

The adaptability of Pleated Cartridge Filters across a broad spectrum of applications further underscores their value. From PTFE Filter Cartridges used in water filtration to those designed for use in air purification, these filters are found in industries ranging from pharmaceuticals to automotive manufacturing. Their ability to handle both particulate and chemical contaminants, maintain filtration precision under varying conditions, and perform efficiently with minimal maintenance makes them an essential tool in modern industrial operations.

For example, in water treatment plants, 5 Micron PTFE Water Filters can remove fine particles and sediments that could otherwise impair the performance of downstream systems. In air filtration, PTFE Membrane Pleated Filters ensure that airborne contaminants are captured without clogging the filter, even during periods of high airflow. These versatile filters play a crucial role in maintaining the integrity of critical industrial systems, where both precision and reliability are paramount.

Conclusion: The Future of Filtration Efficiency

The Pleated Cartridge Filter is rapidly establishing itself as a cornerstone of modern filtration technology. Through its combination of physical filtration, chemical adsorption, and its ability to maintain filtration precision and efficiency under a variety of conditions, it is proving indispensable in industries that require reliable, cost-effective solutions. As demand for cleaner air and water continues to grow, PTFE Filter Cartridges and PTFE Membrane Pleated Filters are likely to see expanded use in both existing and emerging applications.

Whether you are looking to address particulate contaminants in water or air or need to remove harmful chemicals in an industrial process, the Pleated Cartridge Filter stands out as a versatile and high-performing option. With the ability to provide superior filtration in a range of environments, these filters continue to set the standard for quality, reliability, and efficiency in the filtration industry. As companies seek more effective ways to control contaminants while minimizing operational costs, the PTFE Filter Cartridge remains a powerful tool in achieving these goals.