Self-Cleaning Filters in Industrial Wastewater Treatment

DATE:2024-09-07 Number of views: 1 Source:dongwenhui

Wastewater treatment is a critical component of industrial operations, particularly in sectors where large volumes of water are used and contaminated, such as mining, chemical production, and food processing. Managing this wastewater requires robust filtration systems capable of handling various contaminants, ensuring compliance with environmental regulations, and minimizing operational disruptions. Self-cleaning filters (Self-cleaning Filters) have emerged as a highly effective solution, offering automated, efficient filtration processes that reduce manual intervention and downtime. We will explore the role of self-cleaning filters in industrial wastewater treatment, their benefits, and how they compare with other filtration technologies.

The Role of Self-Cleaning Filters in Managing Industrial Wastewater

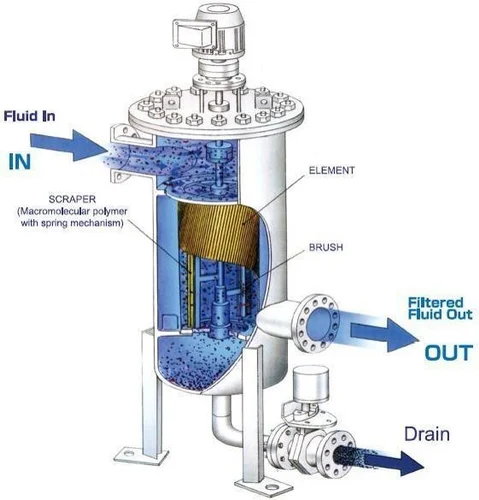

Self-cleaning filters play a crucial role in managing industrial wastewater by automatically removing solid contaminants from large volumes of water without the need for frequent manual cleaning or filter replacement. They operate using a filtration element that traps particulates, and once a certain level of buildup is detected, the system triggers an automated cleaning process. This makes them particularly valuable for industries where downtime is costly and continuous operation is essential.

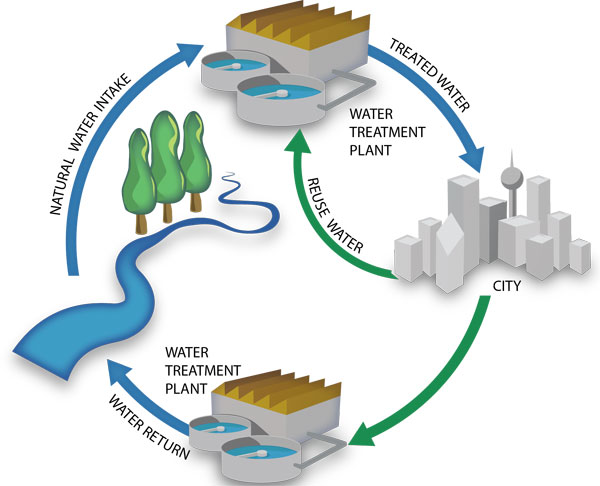

In large-scale industrial plants, Self-cleaning Filters are typically installed at critical points in the wastewater treatment process to ensure that solids like sediment, fibers, or sludge are removed efficiently before the water is either discharged into the environment or sent for further treatment. The automation feature allows for uninterrupted operation, a key advantage in sectors where water filtration must be maintained at all times.

Importance of Removing Solid Contaminants in Key Industries

Industries such as mining, chemical production, and food processing generate wastewater that contains a variety of solid contaminants. For example:

In mining, wastewater can carry heavy metals, sediments, and chemicals used in extraction processes.

In chemical manufacturing, wastewater often contains a mix of chemical byproducts, suspended solids, and organic matter.

In food production, wastewater can contain organic solids, fats, oils, and other residues.

In all these industries, proper removal of solid contaminants is vital to prevent damage to equipment, maintain water quality, and comply with environmental regulations. Self-cleaning Filters excel in this aspect by ensuring that solids are efficiently filtered out before the wastewater is either treated further or discharged.

How Self-Cleaning Filters Prevent Clogging and Reduce Downtime

One of the primary advantages of Self-cleaning Filters in wastewater treatment is their ability to prevent clogging, which is a common problem in other filtration systems that require frequent manual cleaning or replacement. Self-cleaning filters continuously monitor the condition of the filter element and initiate a cleaning cycle as soon as clogging is detected. This automatic cleaning process typically involves backwashing or scraping to remove accumulated particles, ensuring that the filter remains efficient and operational.

By eliminating the need for manual cleaning, Self-cleaning Filters significantly reduce downtime in wastewater treatment facilities. This is especially important in industries that require constant operation, where even brief shutdowns can result in significant production losses or increased maintenance costs.

Comparisons with Other Filtration Technologies

When compared with other filtration technologies, such as membrane filtration, Self-cleaning Filters offer unique advantages in specific applications:

Membrane Filtration: This technology is effective for separating very fine particles and can achieve high levels of filtration. However, membranes tend to clog quickly, especially in environments with high solids content, requiring frequent cleaning or replacement. This can result in higher operational costs and more downtime.

Self-Cleaning Filters: In contrast, Self-cleaning Filters are designed to handle higher solids loads and require less maintenance due to their automatic cleaning feature. While they may not achieve the same level of fine filtration as membranes, they are more efficient for primary filtration of large particles in wastewater with heavy contamination.

For industrial wastewater applications, Self-cleaning Filters are often preferred for their reliability and lower maintenance requirements, especially in pre-filtration stages where the water contains larger solids.

Impact of Stringent Regulatory Environments

Environmental regulations surrounding wastewater discharge have become increasingly stringent across industries. These regulations require companies to meet specific water quality standards before wastewater can be released into the environment. Failure to comply can result in fines, legal action, and reputational damage.

Self-cleaning filters play an essential role in helping companies meet these regulatory standards by ensuring that contaminants are effectively removed from wastewater. Their automated nature ensures that water quality is maintained consistently, which is critical for industries that must adhere to strict environmental laws. By reducing the risk of non-compliance, Self-cleaning Filters help companies avoid penalties while supporting environmentally responsible practices.

FAQ

Why are self-cleaning filters important in wastewater treatment?

Self-cleaning filters are crucial in wastewater treatment because they automate the removal of solid contaminants, reduce the need for manual cleaning, and minimize operational downtime. They offer continuous filtration, making them ideal for large-scale industrial plants that need reliable and efficient water treatment processes.

What types of contaminants do self-cleaning filters remove?

Self-cleaning filters are effective at removing a wide range of solid contaminants from industrial wastewater, including sediment, fibers, organic matter, and suspended solids. The specific types of contaminants depend on the industry, but Self-cleaning Filters are versatile enough to handle various types of debris.

How do self-cleaning filters reduce operational downtime?

By automating the cleaning process, self-cleaning filters prevent the buildup of contaminants that can clog the filtration system. This reduces the need for manual intervention, allowing the system to operate continuously without frequent shutdowns for maintenance or filter replacement.

Can self-cleaning filters handle high viscosity liquids in wastewater?

Yes, self-cleaning filters are designed to handle high viscosity liquids, making them suitable for wastewater applications in industries where the water contains thick or dense contaminants, such as oils, sludges, or chemical residues.

What regulations impact industrial wastewater filtration?

Industrial wastewater filtration is governed by various environmental regulations that dictate the permissible levels of contaminants in discharged water. These regulations vary by region but typically include limits on suspended solids, heavy metals, and other pollutants. Self-cleaning filters help companies meet these regulatory requirements by ensuring that solids are effectively removed from wastewater.

How does Self-cleaning Filter performance compare with membrane filtration?

While membrane filtration provides fine filtration and can remove smaller particles, it is more prone to clogging and requires more frequent maintenance. Self-cleaning filters, on the other hand, are better suited for handling larger particles and higher solids loads, with the added benefit of automatic cleaning to reduce maintenance needs.

What industries benefit most from self-cleaning filters in wastewater treatment?

Industries such as mining, chemical processing, food and beverage production, and agriculture benefit greatly from self-cleaning filters. These sectors generate large volumes of wastewater with varying levels of solid contamination, making Self-cleaning Filters an ideal solution for efficient, cost-effective filtration.

How do self-cleaning filters contribute to sustainable industrial operations?

Self-cleaning filters contribute to sustainability by reducing water waste, minimizing the need for disposable filter elements, and lowering the energy and labor costs associated with manual filtration systems. By automating the filtration process, they help companies achieve more efficient and environmentally friendly wastewater management.

In conclusion, self-cleaning filters offer an advanced, automated solution for industrial wastewater treatment. By efficiently removing solid contaminants and reducing downtime, they help industries meet regulatory standards and improve operational efficiency. As environmental regulations continue to tighten and industries look for more sustainable solutions, the role of self-cleaning filters in wastewater treatment will only grow in importance.

Industry Solutions

Pure Water /Ultra Pure Water System